You are here: Home - Products - Stationary Crushing Plant - Jaw Crusher

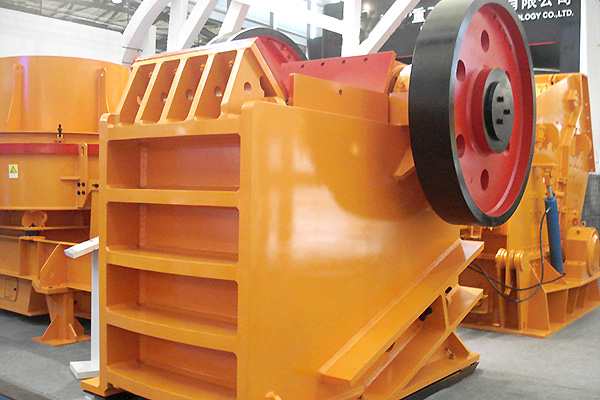

Jaw Crusher

Introduction

Jaw Crusher is mainly used to crush kinds of mining stones primarily, and the largest compression resistance of the material is 320MPa. The PE Series Jaw Crushers is widely used in stone mining, metallurgy industry, building material, highway, railway, and chemical industry. made up of frame, eccentric shaft, grooved wheel, flywheel, moving jaw, side guard plate, toggle plate, toggle backseat, adjusting screw, returning spring, fixed jaw plate and moving jaw plate. Toggle plate is of safety function. PE.PEX Series Single Toggle Jaw Crusher has the features of great crushing ratio, uniform sizes of promance. It can be used to crush material its compressive resistance not more than 320 MPa. It is widely used in various industries, such as mining, smelting, road and railway construction and chemical industry etc. PE Series is used to primary crushing; PEX series is used in secondary crushing and fine crushing.

Performance

1. The application of world-class manufacturing processes and high-tech materials.

2. Integrated steel structures are used for the base of bearing.

3. The crushing chamber uses "V"-shaped structure, so that the feeding size equal to the nominal one.

4. The crushing chamber is deep and without dead zone, increases the capacity and the output.

5. Lubrication system is safe and reliable, convenient to replace parts, easy to maintain.

6. The outlet employs shim adjustment system, convenient and reliable, and increase the flexibility of the equipment.

7. Low noise, less dust.

Global Case

Specification

| Model | Size of Feed Opening(mm) | Max Feed Size (mm) | Discharge Range Opening (mm) | Capacity (m3/h ) | Motor Power(kw) | Weight(t) |

| PE-400×600 | 400×600 | 340 | 40-100 | 10-40 | 30 | 6.5 |

| PE-500×750 | 500×750 | 425 | 50-100 | 28.5-62.5 | 55 | 10.8 |

| PE-600×900 | 600×900 | 500 | 65-160 | 30-75 | 55- 75 | 15 |

| PE-750×1060 | 750×1060 | 630 | 80-200 | 80-160 | 90-110 | 28.9 |

| PE-870×1060 | 870×1060 | 750 | 170-270 | 145-235 | 90-110 | 29.5 |

| PE-900×1200 | 900×1200 | 750 | 100-200 | 100-240 | 110-132 | 49 |

| PE-1000×1200 | 1000×1200 | 850 | 200-280 | 190-275 | 110-132 | 51 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-300 | 250-500 | 200 | 88.5 |

| PEX-150×750 | 150×750 | 120 | 10-40 | 5-16 | 15 | 2.5 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 10-30 | 30-37 | 6.6 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 10-31.5 | 37 | 7 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 12.5-53 | 75 | 12 |

>

>