You are here: Home - Products - Screening & Washing - Linear Vibrating Screen

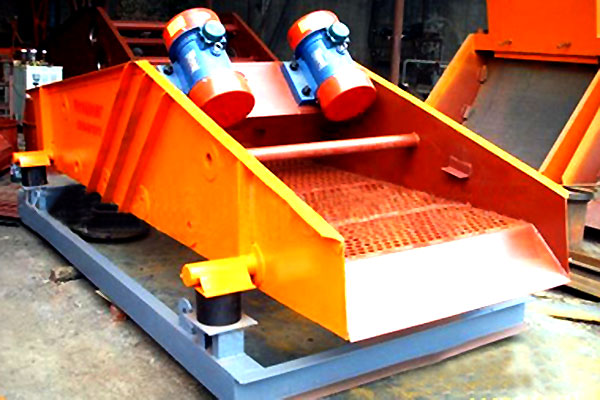

Linear Vibrating Screen

Introduction

Linear vibrating screen adopts double vibration motor drives, when they do synchronous and repeated rotation, vibration forces produced by eccentric blocks offset each other in the direction parallel to motor axis, and fold a resultant force in the direction perpendicular to motor shaft, so the motion trajectory of linear vibrating screen is a straight line.

There is a tilt angle between relative screen surfaces of two motor axises; under the resultant action of vibration force and self-gravitational force, materials on the sieve are thrown up, then they bound ahead by leaps for linear motion, so as to achieve the purpose of screening and grading materials.

Performance

Global Case

Specification

| Product Model | Screen Surface | Max Feed Size (mm) | Mortor Power (kW) | Capacity (t/h) | Weight (kg) | |

|---|---|---|---|---|---|---|

| Deck Size(㎡) | Mesh(mm) | |||||

| ZK1022 | 2.25 | 0.25~50 | <250 | 3×2 | 4.5-90 | 2215 |

| ZK1230 | 3.6 | 0.25~50 | <250 | 4×2 | 7.2-144 | 2693 |

| ZK1237 | 4.5 | 0.25~50 | <250 | 5.5×2 | 9.0-180 | 3118 |

| ZK1437 | 5.25 | 0.25~50 | <250 | 5.5×2 | 12.0-250 | 3210 |

| ZK1445 | 6.3 | 0.25~50 | <250 | 7.5×2 | 12.6-252 | 4040 |

| ZK1637 | 6 | 0.25~50 | <250 | 5.5×2 | 12.0-240 | 3552 |

| ZK1645 | 7.32 | 0.25~50 | <250 | 7.5×2 | 14.4-280 | 4572 |

| ZK1837 | 6.75 | 0.25~50 | <250 | 11×2 | 14.4-270 | 4995 |

| ZK1845 | 8.1 | 0.25~50 | <250 | 11×2 | 16.2-324 | 5436 |

| ZK1852 | 9.45 | 0.25~50 | <250 | 11×2 | 18.9-378 | 5900 |

| ZK2045 | 9 | 0.25~50 | <250 | 11×2 | 16.2-324 | 5969 |

| ZK2052 | 10.5 | 0.25~50 | <250 | 11×2 | 21.0-420 | 6472 |

| ZK2060 | 12 | 0.25~50 | <250 | 15×2 | 24.0-480 | 7558 |

| ZK2445 | 10.8 | 0.25~50 | <250 | 15×2 | 21.6-432 | 7439 |

| ZK2452 | 12.6 | 0.25~50 | <250 | 15×2 | 25.2-504 | 8216 |

| ZK2460 | 14.4 | 0.25~50 | <250 | 15×2 | 28.8-576 | 9235 |

| ZK3045 | 13.5 | 0.25~50 | <250 | 15×2 | 27.0-540 | 9859 |

| ZK3052 | 15.75 | 0.25~50 | <250 | 22×2 | 31.4-628 | 9958 |

| ZK3060 | 18 | 0.25~50 | <250 | 22×2 | 17.5-525 | 11062 |

| ZK3645 | 16.2 | 0.25~50 | <250 | 22×2 | 37.8-756 | 12289 |

| ZK3652 | 18.9 | 0.25~50 | <250 | 22×2 | 43.2-864 | 13409 |

| ZK3660 | 21.6 | 0.25~50 | <250 | 22×2 | 43.2-864 | 14390 |

| ZK3675 | 27 | 0.25~50 | <250 | 30×2 | 54.0-1080 | 17100 |

| 2ZK1022 | 2.25 | 0.25~50 | <250 | 4×2 | 4.5-90 | 3018 |

| 2ZK1230 | 3.6 | 0.25~50 | <250 | 5.5×2 | 7.2-144 | 3740 |

| 2ZK1237 | 4.5 | 0.25~50 | <250 | 7.5×2 | 9.0-180 | 4460 |

| 2ZK1437 | 5.25 | 0.25~50 | <250 | 7.5×2 | 12.0-250 | 5042 |

| 2ZK1445 | 6.3 | 0.25~50 | <250 | 15×2 | 12.6-252 | 6883 |

| 2ZK1637 | 6 | 0.25~50 | <250 | 15×2 | 12.0-240 | 6919 |

| 2ZK1645 | 7.32 | 0.25~50 | <250 | 15×2 | 14.4-280 | 8654 |

| 2ZK1837 | 6.75 | 0.25~50 | <250 | 15×2 | 14.4-270 | 7951 |

| 2ZK1845 | 8.1 | 0.25~50 | <250 | 15×2 | 16.2-324 | 8116 |

| 2ZK1852 | 9.45 | 0.25~50 | <250 | 15×2 | 18.9-378 | 9061 |

| 2ZK2045 | 9 | 0.25~50 | <250 | 15×2 | 16.2-324 | 9133 |

| 2ZK2052 | 10.5 | 0.25~50 | <250 | 22×2 | 21.0-420 | 10128 |

| 2ZK2060 | 12 | 0.25~50 | <250 | 22×2 | 24.0-480 | 10875 |

| 2ZK2445 | 10.8 | 0.25~50 | <250 | 22×2 | 21.6-432 | 11008 |

| 2ZK2452 | 12.6 | 0.25~50 | <250 | 22×2 | 25.2-504 | 12757 |

| 2ZK2460 | 14.4 | 0.25~50 | <250 | 22×2 | 28.8-576 | 13560 |

| 2ZK3045 | 13.5 | 0.25~50 | <250 | 30×2 | 27.0-540 | 15472 |

| 2ZK3052 | 15.75 | 0.25~50 | <250 | 37×2 | 31.4-628 | 16942 |

| 2ZK3060 | 18 | 0.25~50 | <250 | 37×2 | 17.5-525 | 18253 |

| 2ZK3645 | 16.2 | 0.25~50 | <250 | 45×2 | 37.8-756 | 21042 |

| 2ZK3652 | 18.9 | 0.25~50 | <250 | 45×2 | 43.2-846 | 24040 |

| 2ZK3660 | 21.6 | 0.25~50 | <250 | 45×2 | 43.2-846 | 25400 |

>

>