You are here: Home - Products - Stationary Crushing Plant - Hydraulic Cone Crusher

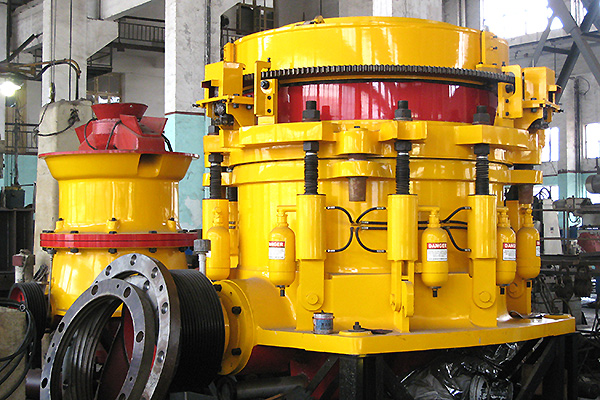

Hydraulic Cone Crusher

Introduction

Hydraulic Cone Crusher is new series product with high performance,which absorbs the advanced technology in the world.It is suitable to crush hard and mid-hard ores and rocks. Hydraulic cone crusher is suitable for crushing various kinds of ores and rocks with medium over hardness and it has the features of reliable structure, high production efficiency, convenient adjustment and economic use. The spring safety system is the overload protection device which is able to make the iron go through the crushing chamber without damaging machine. It adopts two sealing means: dry oil and water to separate stone powders and lubrication grease, thus ensuring reliable work of the machine.

Performance

1. High crushing ratio and production efficiency.

2. Less spare part consumption and low operation cost.

3. Better finished product shape.

4. Hydraulic protection and hydraulic clearing, high automatization and less production stop and repairing time.

5. Thin oil lubrication makes the service time increase.

6. Manifold crushing cavity.

7. Easy maintenance and operation. 8. The crusher can provide customers a higher capacity, better product shape, and easy to be operated.

Global Case

Specification

| Model |

Max Feed Size (mm) |

Discharge Range (mm) |

Power (kw) |

Capacity(t/h)--open circuit, closed discharge(mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 9 | 13 | 16 | 19 | 22 | 26 | 31 | 38 | 51 | ||||

| HPC150C | 165 | 2-31 | 90 | 30-41 | 50-66 | 75-86 | 90-102 | 100-123 | 110-132 | 130-158 | --- | --- |

| HPC150M | 135 | 13-26 | ||||||||||

| HPC150F | 55 | 9-19 | ||||||||||

| HPC200C | 180 | 22-31 | 160 | 55-62 | 70-93 | 100-140 | 130-170 | 160-195 | 175-220 | 195-230 | --- | --- |

| HPC200M | 140 | 13-31 | ||||||||||

| HPC200F | 60 | 9-22 | ||||||||||

| HPC300C | 250 | 26-51 | 200 | 58-72 | 75-98 | 130-150 | 170-210 | 190-220 | 230-260 | 270-298 | 299-322 | 325-350 |

| HPC300M | 160 | 16-38 | ||||||||||

| HPC300F | 80 | 9-22 | ||||||||||

| HPC400C | 300 | 31-51 | 315 | 120-145 | 140-180 | 200-240 | 230-300 | 270-340 | 295-368 | 310-410 | 350-450 | 460-550 |

| HPC400M | 230 | 22-51 | ||||||||||

| HPC400F | 80 | 9-26 | ||||||||||

>

>